Smart Trim, Unique 3-IN-1 Multi-Saw trimmer

Smart Trim: The 3-in-1 Innovation - Loader, positioner, and multi saw trimmer for optimizing wood production

The Smart Trim is an innovative 3-in-1 system that revolutionizes wood processing by combining the functions of loading, positioning, and multi saw trimming in a single compact piece of equipment.

This advanced solution replaces traditional equipment that sometimes can occupy more than 40 feet on a production line by consolidating them into a single device measuring less than 8 feet long. This allows factories to save space, either when adding to their existing facility, during new building construction, or simply to free up space.

The operation of the Smart Trim is based on a lug loader, with a fence system guided by electric servomotors. Controls are programmed on an Allen-Bradley platform.

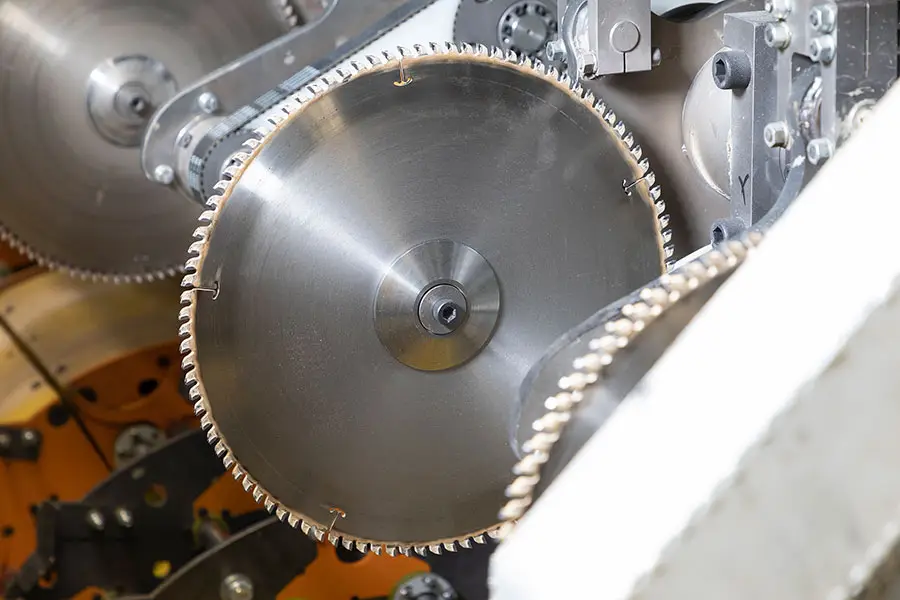

The multi-saw trimmer of SmartMill, the Smart Trim, stands out for its unparalleled versatility, allowing for the production of all possible lengths with multiple cuts to generate maximum value. It offers minimal footprint, the lowest operating cost, and requires very little maintenance. In addition, it is possible to do cut-in-two and even do Precision-End Trimmed (PET) lumber for the cut-in-two! In any case, all the wood cuts can be made without needing to reposition the saws between different lumber productions. This allows the customer to save time between his productions.

The lug loader integrated into the Smart Trim automatically adapts to most wood sizes without requiring manual adjustments. It is capable of loading boards of different sizes at speeds exceeding 150 pieces per minute, ensuring fast and efficient operation.

The positioning system integrated into the Smart Trim uses an optimizer to accurately position the pieces before end-trimming, whether the wood is green or dry. It is controlled by electric servomotors and provides real-time cutting data.

In summary, our multi-saw trimmer is a versatile and efficient solution for sawmills and planing factories looking to optimize their production line while reducing costs and footprint. Moreover, this multi-saw trimmer can be offer with a line shaft or with multi-motor.

Why Our Customers Chose the 3-in-1 Smart Trim system

- Rotary tong loader principle of operation

- Electrically servo driven positioning

- Allen-Bradley plc controls

- Zero-line validation with scanner

Benefits of the Smart Trim

- Unmatched flexibility to produce virtually any length

- Multiple cuts for highest value

- Smallest foot print

- Lowest cost of operation

- Virtually maintenance free

- Multi-saw trimmer

Technical specifications

Trim Accuracy

0.030 in.

Displacement

Up to 12 in.

Speed

Up to 150 lug/min.

Trim Length

Virtually infinite

Precision End Trim

Yes

Multiple cuts

Up to 5

Footprint

10 ft

Communication

Ethernet

Mr David Bouchard

Vice-President, Bois Lemelin

“As part of a modernization project for our Planer Mill, we selected the Smart Trim system for several reasons. As it is a 3-in-1 system, it required little space, less than 8 feet long compared to more than 20 feet for systems from competing brands.

In addition, the Smart Trim now allows us to produce on the same production all possible lengths with incomparable trimming precision.

In short, combine with our optimizer, Smart Trim allows us to create value and ensure the profitability of our operations. We will not hesitate to recommend SmartMill and their Smart Trim in the future. ”