SmartMill SLMA Associate Member Spotlight

SmartMill SLMA Associate Member Spotlight

SmartMill is a team of dedicated experts committed to the success of the wood processing industry. We foster the development of sustainable partnerships with all our customers. We design, manufacture, and install state-of-the-art automation equipment to help customers reach their full performance and profitability potential. SmartMill is present in all Southern Yellow Pine States. With our most recent installation in the U.S., SmartMill positioned itself as a robot & automation expert: |

Here is some of the equipment that SmartMill offers:

SLMA members can see SmartMill as process experts and a key partner in their goal to reach their business achievement. At SmartMill, customer satisfaction is at the heart of their business strategy. |

Do you know the advantages of Automated Agriculture in a Controlled Environment?

This type of agriculture allows continuous autonomous production and an automated harvesting in a 100% controlled climate. This means there is no use of pesticides or fungicides, and this results in consistent products as well as more control and predictability in production.

Automation technology applied to agriculture and provided by our SmartMill-Agricultural Mechatronics division, enables up to 6 times more efficiency than greenhouse farming and requires up to 95% less water than field agriculture.

Learn more about the advantages of adding high technology, produced by SmartMill-Agricultural Mechatronics, at the service of food autonomy.

SmartMill breaks into the Eurozone with the sale of a Smart Trim system in Germany.

Jean Bérubé, president of SmartMill, confirmed the signing of a new contract that includes the sale and installation of the Smart Trim system to Ante-Holz GmbH, the largest timber producer in Germany.

“This innovative trimming technology, a Quebec invention, is already benefiting of a significant success in Canada and the United States. Today, I am very proud to confirm the breakthrough of the Smart Trim in the European market, hand by hand with one of the largest players in the wood industry in Europe,” adds Mr. Bérubé.

This new partnership confirms SmartMill’s position as a leader in the forest industry with a unique offer of technological solutions for sawmills. In this regard, Mr. Bérubé confirms “we are currently in discussions with other mills in Europe and we are convinced of its success in this new market”

ABOUT THE SMART-TRIM

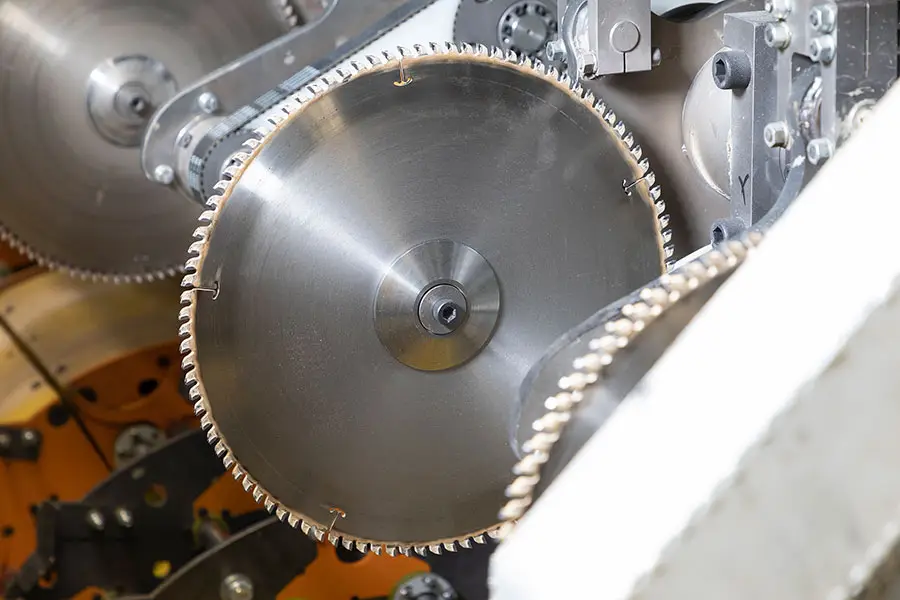

The SMART-TRIM combines three pieces of equipment in one: a Lug loader, a positioning system and a multi-saw trimmer. The result of this technology is the capability to produce infinite lumber lengths.

3-IN-1 INTEGRATED SYSTEM

Lug Loader

Positioning/Fencing System

Multiple Saw Trimmer

SMART-TRIM ADVANTAGES

Smallest footprint

Versatility: all possible lengths

Access to value added niche markets

Eliminates production setup time

ABOUT SMARTMILL

SmartMill is a team of dedicated experts committed to the success of the wood processing industry. We foster the development of sustainable partnerships with all our customers. We design, manufacture, and install state-of-the-art automation equipment that is a customizable solution to improve the profitability of our clients. SmartMill is present in all Southern Yellow Pine States.

For more information, please contact us!

SmartMill’s talent recognized in the Forestry Rising Stars Awards of 2022.

It is with great pride that we announce that Marc-Olivier Lachance, our automation specialist, has been selected in the Forestry Rising Stars Awards of 2022.

Having started his career as an intern at VAB Machines back in 2018, he was one of our first employees when this company became SmartMill. His meticulous work, his attitude of service, his commitment, and his genius in proposing solutions aimed to offer the best equipment to our customers makes him a rising star in the 2022 forestry industry.

To learn more, click here (article in French).

SmartMill joins the Grouping of Industrial Automation Companies.

We are very happy to announce that SmartMill has joined the Grouping of Industrial Automation Companies (REAI). This organization aims to promote intelligent automation solutions to accelerate the digital transformation in Quebec’s industrial sector and by this, encourage the production of projects that otherwise could be produced elsewhere.

One of the REAI’s objectives is to represent the interests of our industry to government and institutional bodies in order to present the know-how and the leaderships of the companies belonging to the Grouping.

The REAI seeks to make of Quebec a model in the automation industry through a collaborative networking dynamic among its members.

For SmartMill it’s an honor to be part of the REAI since it is formed by a group of innovative companies that create value through automation, one of the core values of our company.

SmartMill signs representation agreement with Finna Sensors

SmartMill management team announced the signing of a representation agreement with Finna Sensors.

“We are very proud to have finalized this agreement with Finna Sensors that allows them to promote our state-of-the-art equipments and at the same time will allow us to advertise and sale their innovative products” says Jean Bérubé, Eng., president SmartMill.

“With this agreement, we are able to represent their products in eastern Canada, North-eastern United States and South-eastern US as well”, adds M. Bérubé.

The products concerned by this agreement are a true complement to each other’s functionality and are the following:

-

Finna: Transverse HD Hybrid moisture/density sorting system. An outstanding tool for sorting heavy and frozen lumber by moisture and density.

-

Finna: Planer moisture systems for optimizing grade recovery and yield.

-

SmartMill: FLX-800, a test bench allowing to determine the MOE and the MOR of wood boards.

In this regard, “Finna Sensors is excited to collaborate with SmartMill and Dynalyse to create an ideal combination of systems and service, providing valuable solutions for customers in (Eastern) Canada,” said Jason Kovacik, Sales Manager at Finna Sensors

SmartMill and Finna Sensors aim to provide high-tech solutions in automation for the wood industry in order to help our clients get the maximum of value of each piece of lumber and maximise their profitability in the process.

About SmartMill

SmartMill is a team of dedicated experts committed to the success of the wood processing industry. SmartMill designs, manufacture and install state-of-the-art automation equipment that is a customizable solution to improve the profitability of its clients located in North America.

New Important Contracts for SmartMill.

SmartMill is pleased to announce the signing of the following contracts:

- Smart-Trim 3-IN-1 system sold to MC Dixon Lumber Co, a Southern Yellow Pine Mill located in Eufaula in southeast Alabama, USA. This new contract covers the sales & installation of a 16 Foot 3-IN-1 Smart-Trim System.

- SmartFence sold to NorSask Forest Products, a SPF Mill located in Meadow Lake, Saskatchewan, Canada. This new contract covers the sales & installation of a new 4 Axes Smart Fence system at the Planer Mill.

About the Smart-Trim

Unique in North America, the Smart-Trim is a 3-IN-1 system combines three pieces of equipment in one : a lug loader, a positioning system and a multi-saw trimmer in 8 feet space. The result is the capability to produce infinite lumber lengths. The Smart-Trim is a technological revolution setting new standards in the wood processing industry. For more information on the Smart-Trim, contact our specialists.

Smallest footprint

Versatility: all possible lengths

Access to value added niche markets

Eliminates production setup time

About the SMART FENCE

The SMART FENCE system is the most accurate and yet smallest fencing system ever built in the industry. This system uses the optimizer’s solutions to accurately position lumber boards prior to trimming operation for green or dry lumber Mills. . For more information on the Smart-Fence, contact our specialists.

Chips, Inc., selects SmartMill’s Lug Loader to increase lug-fill percentages – testimonial video.

Chips, Inc. has made several improvements to its southern pine sawmill over the past five years to improve its production and yield at the mill’s location in Troy, Va. The company’s latest investment, a SmartMill lug loader, has reduced bottlenecks and increased production nearly 5MBF per hour since completing the project in July 2021.

Vice-president Jordan Diehl says a new debarker and gang put pressure on their existing 24-year-old hook-stop board feeder and production outgrew the trimmer infeed. “We knew we needed to do something because the trimmer was backing up and the operator was getting his butt kicked everyday handling way too many pieces,” he says of their lug loader purchase.

Diehl says one of the biggest takeaways was increasing lug-fill percentages and hourly production from 22MBF per hour to 27MBF. (Chips, Inc. accepts no larger than 20 in. logs and its average small-end diameter is 9.7 in.).

The SmartMill lug loader is essentially maintenance free and the operator’s handling job has switched to a process surveillance role. “The lug loader is all electric and air so there’s hardly any maintenance. We haven’t had to work on it hardly at all the past eight months,” Diehl says.

Chips, Inc. was very satisfied working with SmartMill under Berube’s leadership and says the lug loader investment has already paid dividends. “They make a great product and see the project all the way through to the end,” Diehl affirms. “It has really paid off for us.”

SmartMill signs contract to supply cutting-edge technology to Bio Serra Harwood, a division of Mono Serra Group.

SmartMill signs contract to supply new cutting-edge technology to Bio Serra Hardwood, a division of Mono Serra Group.

SmartMill president, Jean Berube, has announced the signing of a new contract with Mono Serra Group to supply equipment for its Bio Serra Hardwood Mill located in Saint-Monique, Quebec, Canada. The contract includes the sale and installation of the unique SMART-TRIM technology system in North America and a Smart Lug Loader.

“This new cutting-edge technology will allow Bio Serra Hardwood Mill to substantially increase its production efficiency by rapidly increasing its productivity and the quality of its products,” says Jean Berube.

This new contract confirms the position of SmartMill as an industry leader, with its unique offer of innovative technology solutions for optimizing operations for its business partners, added Berube.

ABOUT THE SMART-TRIM:

SMART-TRIM is the result of more than 4 years of a research and development program involving specialists in conception and in mechanical, electrical and movement design. SMART-TRIM combines three pieces of equipment in one: a Lug loader, a positioning system and a multi-saw trimmer. This unique system uses the optimizer’s solutions to index, position, and trim green or dry, rough or dressed lumber.

ABOUT SMARTMILL:

SmartMill designs and develops integrated solutions to improve and optimize factory production and manufacturing processes. SmartMill is a team of dedicated experts committed to the success of our clients. In this regard, we encourage the development of sustainable partnerships with all our customers around the world. In order to meet the ever-increasing demand for products that meet high quality standards, we design, manufacture and install automated state-of-the-art equipment that is a customizable solution to preserve and even increase the profitability of companies. As of today, SmartMill exports more than 80% of their solutions.